一般的な紙パッケージのカラーボックス14種類

If you’re aiming for exceptional packaging design, you cannot overlook the significance of packaging box types. We’ve compiled a list of 14 common paper packaging color box types!

In today’s market, the emphasis on product packaging is increasingly evident. The variety of packaging boxes available is astonishing. They not only elevate the product’s quality and appeal but also enhance the pleasure of using it. Packaging boxes that are stylish, convenient, simple, yet elegant, play a crucial role in sales and brand development.

For designers keen on crafting attention-grabbing packaging, familiarity with several classic box shapes is essential. With myriad box types and structures available, designers can innovate within the basic framework, creating dynamic shapes and lending a unique flair to product packaging.

Below are some classic packaging box types:

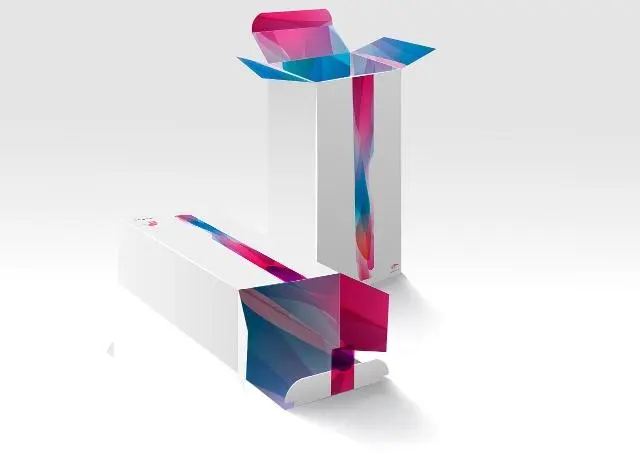

- Ordinary Box Type (Reverse Mortise Lock Box): This is a very common box type, there are many on the market, and the design structure is relatively simple. Despite its simple structure, it can be called the originator of paper packaging boxes and the most original box type.

- Advantages: Easy and cheap to produce.

- Disadvantages: Common, with a low sense of uniqueness.

However, with creative design, even this simple box can stand out on the shelf.

- Aircraft Cover Box Type: Airplane boxes are mainly used to package some goods that are not too large and are easy to transport. Its unfolded shape is more like an airplane, hence its name. After the packaging box is spread out, it becomes a whole piece of chopped paper, which is integrated using structural design. There is no need to glue the box, which can save processing costs.

-

- Advantage: Excellent pressure resistance and easy to fold.

- Note: Avoid complex patterns during printing due to non-precision printing methods.

-

- Heaven and Earth Cover Box Type: According to the shape of the “cover”, the heaven and earth cover boxes can be divided into square heaven and earth cover boxes, rectangular heaven and earth cover boxes, round heaven and earth cover boxes, heart-shaped heaven and earth cover boxes and special-shaped heaven and earth cover boxes. A variety of ceiling and floor cover boxes are used in various industries and have wide adaptability.

-

- They can be automatically produced, enhancing efficiency and reducing manual errors.

-

- Pull-Out Box Type: The box is shaped like a drawer and has a classic pull-out structure. It is composed of a box body and a drawer, which is easy to pull out and push closed. It is divided into two parts: lid and fitting. The box body is also called the outer box, and it has two forms: one-side opening and two-side opening. This box-shaped double-layer structure also has the characteristics of a pull-out form, so it is solid and easy to use.

- Polygonal Box Type: The box shape is composed of pentagons or hexagons or even more polygons. The overall shape is much more refined than ordinary ones. It is often used as gift boxes, giving people a stable and atmospheric feeling and leaving a deep impression on consumers.

- Window Box Type: The window box type is a carton with holes cut out and windows or transparent cellophane attached to facilitate the see-through of the product, allowing the product to be displayed intuitively in front of us, making it easier for customers to observe, allowing consumers to select products more intuitively, and increasing the credibility of the product. degree, and improve consumers’ decision-making power to purchase. Products with beautiful appearance can highlight their advantages and become more competitive.

- Design tip: Utilize the window for creative associative designs.

- Design tip: Utilize the window for creative associative designs.

- Special-Shaped Box: The focus of special-shaped boxes lies in the particularity of the structure and the attractive appearance. Therefore, the creative design and production methods of special-shaped boxes are more difficult than other box types. However, the special-shaped box packaging design has a unique structure and rich artistry and practicality. The uniqueness lies in the addition and subtraction of the box’s surface, shape, quantity, and direction. It can be made into various shapes and is mostly used for gift packaging.

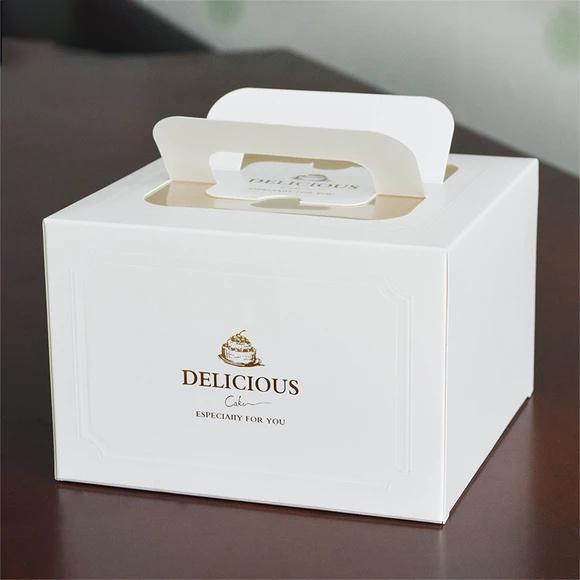

- Portable Box Type: The suitcase has a good load-carrying capacity, a portable upper part, and is easy to assemble and disassemble. It is the most commonly used box type in gift boxes. Its biggest feature is that it is easy to carry. However, you should pay attention to whether the volume, weight, material and handle structure of the product are equivalent to avoid damage during use.

- Hanging Box Type: Hanging packaging can enable batteries, stationery, toothbrushes, headphones and other small commodities to appear in the best position and angle in the supermarket, which is conducive to shelf display.

- Display Box Type: Among today’s dazzling array of products, the first thing that catches people’s eyes is often the products in the display box. Display box packaging plays a very important role in the sales of goods, especially its role in attracting consumers, increasing product added value, satisfying consumers’ spiritual needs, and consolidating the brand and corporate image. It is increasingly recognized by people. At present, It is widely used in blind boxes and figures.

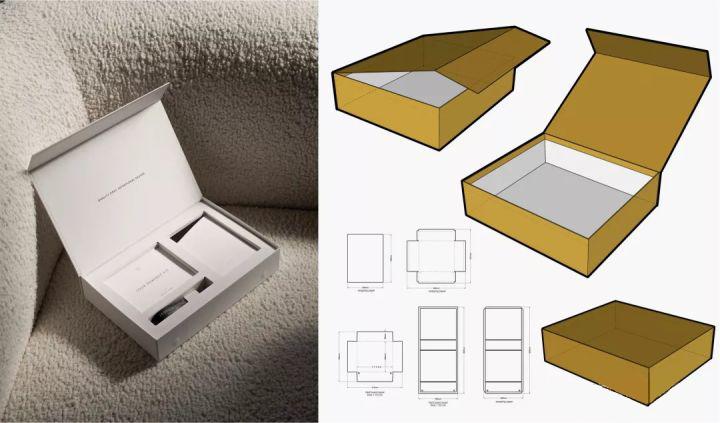

- Book Box Type: The packaging style is like a book, and the box opens from the side. The shape box is composed of a panel and a bottom box. The materials are selected according to the customized size and function of the packaging box. Some box types are divided into single flip lid boxes and double flip lids. The double flip lids are composed of a bottom box and two covers. The requirements for a double clamshell packaging box The process is relatively complex. Matching magnets, iron sheets and other materials according to needs, it is one of the box options for high-end gifts.

- Double Door Box Type: The double-door box type consists of a left outer box and a right outer box. There is an inner box on the inside, and the left and right outer boxes are symmetrical. It is novel in style, easy to use, beautiful in appearance, easy to manufacture, low in cost, and easy to promote; it can conveniently and quickly accommodate a variety of Packaging boxes of different specifications and tastes.

- Folding Box Type: Folding cartons occupy a place in many fields with their novel structures and gorgeous decorations. Leave a certain distance between the bends of the box-shaped box. When in use, it can be propped up into a three-dimensional shape and can be folded freely. It can not only play a certain protective function, but also bring higher added value to the goods to a certain extent. Therefore, folding cartons are becoming more and more popular.

- Swivel Box Type: The rotating window display packaging box has an exquisite structural design, which can beautify and promote the product, reflect the value of the product, and improve the competitiveness of similar products in the market. The rotating box loads and displays products without the need for other materials during display. It protects the products very well during packaging and is easy to pick up and place. It improves convenience of use, reduces costs, and is highly practical.

These packaging box types offer diverse options for designers to create compelling and functional packaging solutions.