14 gängige Papierverpackungen mit farbigen Schachteln

Wenn Sie ein außergewöhnliches Verpackungsdesign anstreben, dürfen Sie die Bedeutung der Verpackungsschachtelarten nicht übersehen. Wir haben eine Liste mit 14 gängigen Farbkartons für Papierverpackungen zusammengestellt!

Auf dem heutigen Markt liegt der Schwerpunkt immer mehr auf der Produktverpackung. Die Vielfalt der verfügbaren Verpackungen ist erstaunlich. Sie erhöhen nicht nur die Qualität und Attraktivität des Produkts, sondern steigern auch die Freude am Gebrauch. Verpackungsschachteln, die stilvoll, praktisch, einfach und dennoch elegant sind, spielen eine entscheidende Rolle für den Absatz und die Entwicklung der Marke.

Für Designer, die aufmerksamkeitsstarke Verpackungen entwerfen wollen, ist die Vertrautheit mit verschiedenen klassischen Schachtelformen unerlässlich. Dank der unzähligen Schachtelarten und -strukturen können Designer innerhalb des Grundgerüsts innovativ sein, dynamische Formen schaffen und der Produktverpackung ein einzigartiges Flair verleihen.

Im Folgenden sind einige klassische Verpackungsarten aufgeführt:

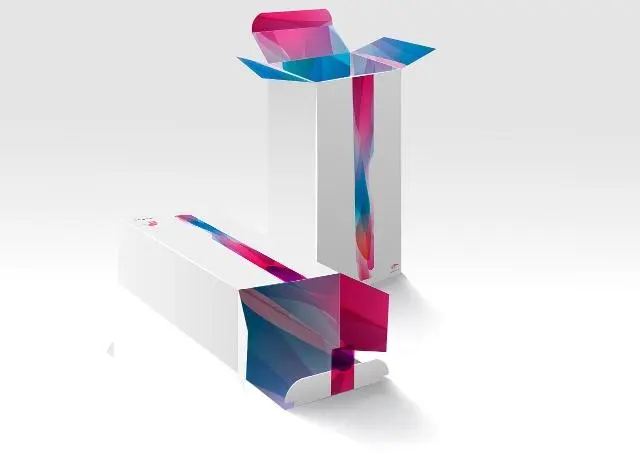

- Gewöhnlicher Box-Typ (Reverse Mortise Lock Box): Es handelt sich um einen sehr verbreiteten Schachteltyp, von dem es viele auf dem Markt gibt, und dessen Designstruktur relativ einfach ist. Trotz ihrer einfachen Struktur kann man sie als die Urform der Papierverpackungen und als die originellste Schachtelart bezeichnen.

- Vorteile: Einfach und billig in der Herstellung.

- Benachteiligungen: Gewöhnlich, mit einem geringen Gefühl der Einzigartigkeit.

Mit einer kreativen Gestaltung kann aber auch diese einfache Schachtel im Regal auffallen.

- Flugzeugabdeckung Box Typ: Flugzeugkartons werden hauptsächlich zum Verpacken von Waren verwendet, die nicht zu groß und leicht zu transportieren sind. Seine aufgeklappte Form ähnelt eher einem Flugzeug, daher sein Name. Nachdem die Verpackungsschachtel ausgebreitet ist, wird sie zu einem ganzen Stück zerkleinerten Papiers, das mit Hilfe von Strukturdesign integriert wird. Der Karton muss nicht geklebt werden, was die Verarbeitungskosten senken kann.

-

- Vorteilhaft: Ausgezeichnete Druckfestigkeit und leicht zu falten.

- Hinweis: Vermeiden Sie komplexe Muster während des Drucks, da die Druckverfahren nicht präzise genug sind.

-

- Himmel und Erde Cover Box Typ: Je nach Form des "Deckels" lassen sich die Himmel- und Erdabdeckungskästen in quadratische Himmel- und Erdabdeckungskästen, rechteckige Himmel- und Erdabdeckungskästen, runde Himmel- und Erdabdeckungskästen, herzförmige Himmel- und Erdabdeckungskästen und sonderförmige Himmel- und Erdabdeckungskästen einteilen. Eine Vielzahl von Decken- und Bodenabdeckkästen wird in verschiedenen Branchen eingesetzt und ist sehr anpassungsfähig.

-

- Sie können automatisch erstellt werden, was die Effizienz erhöht und manuelle Fehler reduziert.

-

- Ausziehbare Box Typ: Die Box ist wie eine Schublade geformt und hat eine klassische Auszugsstruktur. Sie besteht aus einem Kastenkörper und einer Schublade, die sich leicht herausziehen und schließen lässt. Sie ist in zwei Teile unterteilt: Deckel und Beschlag. Der Kastenkörper wird auch als Außenkasten bezeichnet und hat zwei Formen: einseitige Öffnung und zweiseitige Öffnung. Diese doppelschichtige Kastenstruktur hat auch die Eigenschaften einer ausziehbaren Form, so dass sie solide und einfach zu benutzen ist.

- Polygonal Box Typ: Die Kastenform setzt sich aus Fünfecken, Sechsecken oder noch mehr Polygonen zusammen. Die Gesamtform ist viel raffinierter als gewöhnliche Formen. Sie wird häufig als Geschenkboxen verwendet, die den Menschen ein stabiles und stimmungsvolles Gefühl vermitteln und einen tiefen Eindruck bei den Verbrauchern hinterlassen.

- Fensterbox Typ: Der Fensterkarton ist ein Karton mit ausgeschnittenen Löchern und angebrachten Fenstern oder durchsichtigem Zellophan, um die Durchsicht auf das Produkt zu erleichtern, so dass das Produkt intuitiv vor unseren Augen präsentiert werden kann, was den Kunden die Beobachtung erleichtert, die Auswahl der Produkte intuitiver macht und die Glaubwürdigkeit des Produkts erhöht. und die Kaufentscheidungsfähigkeit der Verbraucher verbessert. Produkte mit schönem Aussehen können ihre Vorteile hervorheben und wettbewerbsfähiger werden.

- Gestaltungstipp: Nutzen Sie das Fenster für kreative, assoziative Gestaltungen.

- Gestaltungstipp: Nutzen Sie das Fenster für kreative, assoziative Gestaltungen.

- Speziell geformte Box: Der Schwerpunkt von Schachteln in Sonderform liegt in der Besonderheit der Struktur und dem attraktiven Aussehen. Aus diesem Grund sind die kreative Gestaltung und die Produktionsmethoden für Schachteln in Sonderform schwieriger als bei anderen Schachtelarten. Das Verpackungsdesign von Schachteln in Sonderform weist jedoch eine einzigartige Struktur auf und ist reich an künstlerischen und praktischen Aspekten. Die Einzigartigkeit liegt in der Addition und Subtraktion der Oberfläche, der Form, der Menge und der Richtung der Schachtel. Sie kann in verschiedenen Formen hergestellt werden und wird meist für Geschenkverpackungen verwendet.

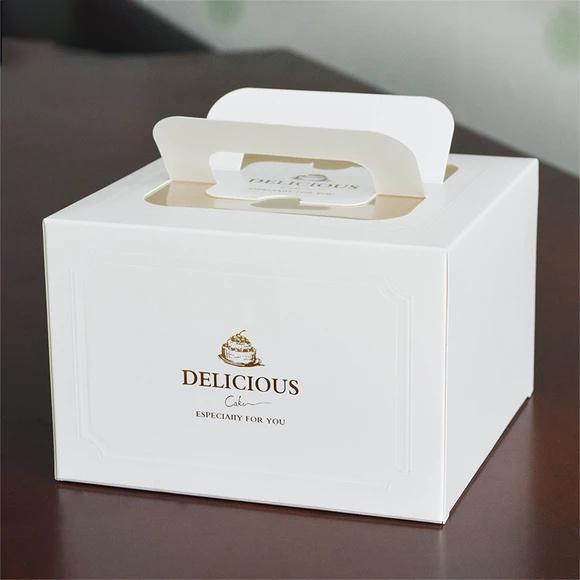

- Tragbare Box Typ: Der Koffer hat eine gute Tragfähigkeit, ein tragbares Oberteil und lässt sich leicht zusammenbauen und auseinandernehmen. Er ist der am häufigsten verwendete Koffertyp bei Geschenkkartons. Sein größtes Merkmal ist, dass er leicht zu tragen ist. Sie sollten jedoch darauf achten, dass das Volumen, das Gewicht, das Material und die Griffstruktur des Produkts gleichwertig sind, um Beschädigungen während des Gebrauchs zu vermeiden.

- Hängebox Typ: Hängeverpackungen ermöglichen es, Batterien, Schreibwaren, Zahnbürsten, Kopfhörer und andere kleine Waren in der besten Position und im besten Winkel im Supermarkt zu präsentieren, was der Auslage im Regal förderlich ist.

- Display Box Typ: Bei der heutigen schillernden Vielfalt an Produkten fällt das erste, was den Menschen ins Auge fällt, oft die Verpackung der Produkte. Die Verpackung von Schaukästen spielt eine sehr wichtige Rolle beim Verkauf von Waren, insbesondere bei der Anziehung der Verbraucher, der Erhöhung des Produktmehrwerts, der Befriedigung der geistigen Bedürfnisse der Verbraucher und der Konsolidierung des Marken- und Unternehmensimages. Sie wird von den Menschen zunehmend anerkannt. Gegenwärtig wird er häufig für Blindschachteln und Figuren verwendet.

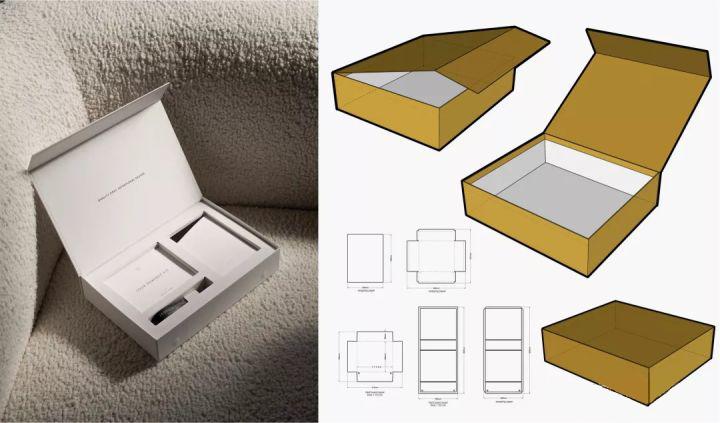

- Buch Box Typ: Die Verpackung ist wie ein Buch gestaltet, und die Schachtel lässt sich von der Seite öffnen. Die Formschachtel besteht aus einem Paneel und einer Bodenschachtel. Die Materialien werden entsprechend der individuellen Größe und Funktion der Verpackungsschachtel ausgewählt. Bei einigen Schachteltypen wird zwischen Einzel-Klappdeckelschachteln und Doppel-Klappdeckeln unterschieden. Die Doppelklappdeckelschachteln bestehen aus einer Bodenschachtel und zwei Deckeln. Die Anforderungen an eine Doppelklappdeckel-Verpackungsschachtel Das Verfahren ist relativ komplex. Je nach Bedarf werden Magnete, Eisenbleche und andere Materialien verwendet, so dass diese Schachtel eine der Optionen für hochwertige Geschenke ist.

- Doppeltür Box Typ: Der zweitürige Kastentyp besteht aus einem linken und einem rechten Außenkasten. Auf der Innenseite befindet sich ein Innenkasten, und der linke und der rechte Außenkasten sind symmetrisch. Sie ist neuartig im Stil, einfach zu benutzen, schön im Aussehen, einfach herzustellen, kostengünstig und leicht zu vermarkten; sie kann bequem und schnell eine Vielzahl von Verpackungskästen mit unterschiedlichen Spezifikationen und Geschmacksrichtungen aufnehmen.

- Faltschachtel Typ: Faltschachteln nehmen mit ihren neuartigen Strukturen und prächtigen Verzierungen in vielen Bereichen einen Platz ein. Lassen Sie einen gewissen Abstand zwischen den Biegungen der kastenförmigen Schachtel. Wenn sie in Gebrauch ist, kann sie in eine dreidimensionale Form gebracht werden und frei gefaltet werden. Sie kann nicht nur eine gewisse Schutzfunktion erfüllen, sondern auch in gewissem Maße einen höheren Mehrwert für die Waren bringen. Daher erfreuen sich Faltschachteln immer größerer Beliebtheit.

- Schwenkbare Box Typ: Die drehbare Display-Verpackungsbox hat eine exquisite Struktur, die das Produkt verschönern und fördern, den Wert des Produkts widerspiegeln und die Wettbewerbsfähigkeit ähnlicher Produkte auf dem Markt verbessern kann. Die rotierende Schachtel lädt und präsentiert Produkte, ohne dass andere Materialien für die Präsentation benötigt werden. Sie schützt die Produkte während des Verpackens sehr gut und lässt sich leicht aufheben und platzieren. Sie verbessert die Benutzerfreundlichkeit, senkt die Kosten und ist äußerst praktisch.

Diese Verpackungsschachteltypen bieten Designern vielfältige Möglichkeiten, ansprechende und funktionale Verpackungslösungen zu gestalten.