Wissen Sie, wie Wellpappe hergestellt wurde?

1884 entwickelte der schwedische Chemiker Carl F. Dahl ein Verfahren zum Aufschluss von Holzspänen zu einem starken Papier, das reiß-, spalt- und platzfest ist. Er nannte es das Kraft-Verfahren, weil es ein starkes Papier erzeugt, das reiß-, spalt- und platzfest ist.

Die Produktionslinie für Wellpappe umfasst hauptsächlich die folgenden Maschinen: einseitige Wellpappenanlage, doppelseitige Anlage, Heizplatte, Längsschneide- und Spaltpressenlinie, Querschneideanlage und Wellpappenstapel.Wellpappe wird aus gewölbtem Papier hergestellt, das als "Riffelung" bekannt ist.Es handelt sich um eine ziemlich hochtechnologische Lösung, die fortschrittliche Computerdesign- und Fertigungssysteme verwendet. Aufgrund dieses Designs ist Wellpappe für viele Verpackungsdesigner die beste Wahl.

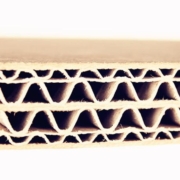

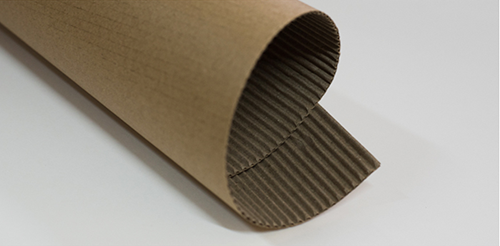

Ein fertiges Stück Wellpappe besteht aus einer einzelnen Wellpappenschicht, die zwischen zwei Deckschichten (siehe oben) eingebettet ist. Die drei Schichten werden durch Kleister miteinander verbunden, der aus Wasser, Stärkepaste, Natronlauge, Borax und einigen Zusatzstoffen besteht. Der Einsatz des Kleisters ist der Schlüssel zur Qualität der Verklebung von Wellpappe.

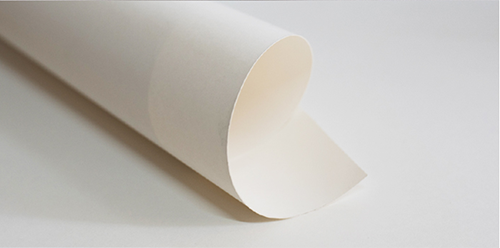

Deckschichten

Wellpappendeckel werden in den folgenden Qualitäten hergestellt:

Kraft Liner - Das hochwertigste Papier für die Deckschicht, das mit einem Anteil von 80% Sulfatzellstoff hergestellt wird

Testliner - Mehrschichtiges Papier aus verschiedenen Fasermaterialien, der Zellstoffanteil ist nicht festgelegt, daher werden nur die Festigkeitseigenschaften definiert und garantiert.

Schrenz (grau) - Papier minderer Qualität, das aus Recyclingpapier hergestellt wird.

Riffelung

Riffelungen werden in den folgenden Qualitäten hergestellt:

Halbzell stoff -Hochwertiges Papier, sehr festes, halbzelliges Papier aus Holzfasern

Wellen stoff - Graues Papier aus sortiertem (hochwertigem) Recyclingpapier

schrenz(grau) - minderwertiges Papier aus Recyclingpapier.

Die Herstellung von Wellpappe umfasst zwei wichtige SchritteHerstellung von Kraftpapier und Wellpappe. Bei der Herstellung von Kraftpapier werden die Holzspäne zerkleinert und die entstehende Papiermasse durch massive Dampfwalzen geleitet, die das Wasser entfernen.

Die Wellpappenherstellung erfolgt ebenfalls in einer Maschine, die schwere Walzen verwendet. Eine Papprolle wird gewellt und dann mit der gleichen Maschine zwischen zwei andere Lagen (Liner) geklebt. Der Kleber wird dann ausgehärtet, indem die Pappe über erhitzte Walzen geführt wird.

Eine qualifizierte Wellpappe sollte die folgenden Normen erfüllen:

- Der Klebstoff des Kartons ist gut.

- Die Riffelform ist gut und ohne Riffelphänomen.

- Die Wellpappe ist flach, nicht gewölbt oder verzogen, um die Härte zu gewährleisten.

Künftige Wellpappenbehälter werden aus Kraftpapier hergestellt, das aus recycelten Verpackungen und nicht aus Bäumen gewonnen wird. Recycling und andere umweltfreundliche Verfahren werden in der Zukunft der Wellpappe weiter an Bedeutung gewinnen. Schon heute werden bei der Herstellung von Behältern Druckfarben auf der Basis von Sojaöl sowie biologisch abbaubare Wachse und andere Beschichtungen eingesetzt. Führende Verpackungsunternehmen betreiben bereits Papierfabriken, die frisches, sauberes Kraftpapier herstellen, indem sie gebrauchte Behälter de-inking und pulpen.