Ved du, hvordan bølgepap blev fremstillet?

In 1884, Swedish chemist, Carl F. Dahl, developed a process for pulping wood chips into a strong paper that resists tearing, splitting, and bursting. He named it the Kraft process because it produces a strong paper that resists tearing, splitting, and bursting.

Corrugated board production line mainly includes the following machines:corrugated single side unit,double sided unit,hot plate, longitudinal trimming and split cutting press line, transverse cutting unit and corrugated cardboard stack.Corrugated cardboard is made from arched paper known as ‘fluting’.It’s a fairly high-tech solution that uses advanced computer design and manufacturing systems. It’s this design that makes corrugated cardboard the best choice for many packaging designers.

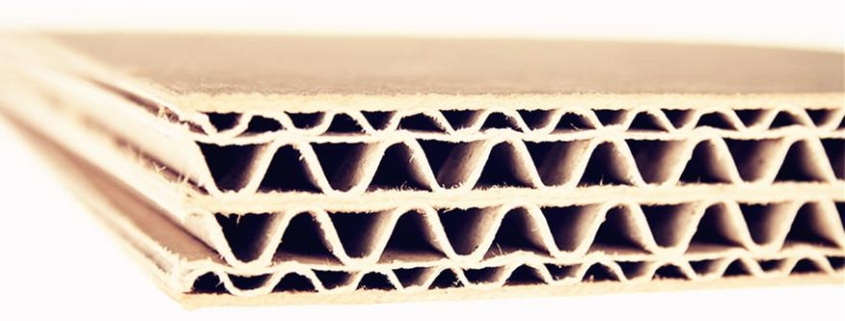

A finished piece of corrugated cardboard consists of a single corrugated layer sandwiched between two cover layers showed above.The three layers are bonded by paste which consist of water, starch paste, caustic soda, borax and some additives. Among them,The deployment of paste is the key to the bonding quality of corrugated cardboard.

Cover layers

Corrugated cardboard covers are produced in the following qualities:

Kraft liner – The highest quality paper for the cover layer that is made with an 80% share of sulphate pulp

Test liner – Multi-layer paper made of different fibrous materials, the proportion of pulp is not determined, therefore only strength properties are defined and guaranteed.

Schrenz (gray) – Least quality paper made from recycled paper.

Fluting

Fluting is produced in the following qualities:

Halbzell stoff -High quality paper, very solid semi-cellular paper made of wood fibers

Wellen stoff – Gray paper made from sorted (high quality) recycled paper

schrenz(gray) – Least quality paper made from recycled paper.

Corrugated cardboard manufacture includes two key steps: making Kraft paper and corrugating the cardboard. Kraft paper involves pulping wood chips and then feeding the resulting paper substance through massive steam rollers that remove the water.

Corrugating is also done in a machine that utilizes heavy rollers. One roll of cardboard is corrugated and then glued between two other layers (liners) by the same machine. The glue is then cured by passing the cardboard over heated rolls.

A qualified corrugated board should meet the following standards:

- The adhesive of cardboard is good.

- The corrugating form is good, and without the corrugating phenomenon.

- The corrugated cardboard is flat, not curved or warped to ensure the hardness.

Future corrugated containers will be manufactured using Kraft paper produced from recycled packaging rather than trees. Recycling and other environmentally friendly processes will continue to grow in importance in the future of corrugated cardboard. Today, inks based on soybean oil and biodegradable waxes and other coatings are beginning to be used in container manufacturing. Leading packaging companies are already operating paper mills that make fresh, clean Kraft paper by de-inking and pulping used containers.

Skriv en kommentar

Vil du deltage i diskussionen?Du er velkommen til at bidrage!