iPhone: The secret of phone package designing and manufacturing

iPhone’s acme user experience won the favorite of users around the world, but Apple is not limited for design of mobile phone itself, from the accessories such as headset to box packaging shows the apple brand exquisite craft, so how the phone box packaging is designed? Picture below showed the dismantling of iPhone’s mobile phone boxes.

The type of the packing box used by iPhone belongs to the “Folding paper box”. It is a cardboard box which uses corrugated paper and other hard cardboard as frame and pastes a layer of thin decorative paper on the surface. Compared to the “plug-in box” and only a piece of thick paper and corrugated paper can be folded into the box, the more rigid, high precision. Moreover, by changing the surface decorative paper, the impression and texture of the package can be adjusted. Most of the high-grade brand packaging such as cakes, gifts and jewelry at home and abroad are covered with leather cartons. However, because of the limitation of mechanical automation production, the cost of pasting paper box is high. Moreover, because of the structural reasons, there are some limitations in the manufacture of cartons.

Take the “corner” of a packing box for example. When making a frame with cardboard, the ordinary paper box should pass through the following procedures. The indentation in the cardboard, and then make out the indentation, along the fold in the peripheral paste decorative paper. At this time, there is a gap between the folding angle. Therefore, when the decorative paper is pasted in the outer circle, it will not form a sharp angle, so that the whole paper box is given a round impression. The appearance of serious and steady, as with the corner of the polished wooden box. That is to say, in order to show the rigidity of the box, the thicker the paper box used, the less angled corner.

But in Apple’s view, packaging boxes as a carrier of iPhone, which displays a sharp impression and displays the characteristics of goods to customers, requires not only strong rigidity but also sharp edges. To this end, the apple carved a 90 – degree groove on the board to make it fold to the inside to form a right angle “V cutting” method. V cutting is not only troublesome, but also requires high precision of processing, so it is very expensive. Of the most common packaging of this processing method, 1 Bvlgari chocolates, which are priced at $13, belong to this kinds of packaging. On the basis of the V cutting technique, the apple has been made into a simple, rigid package through multiple improvements.

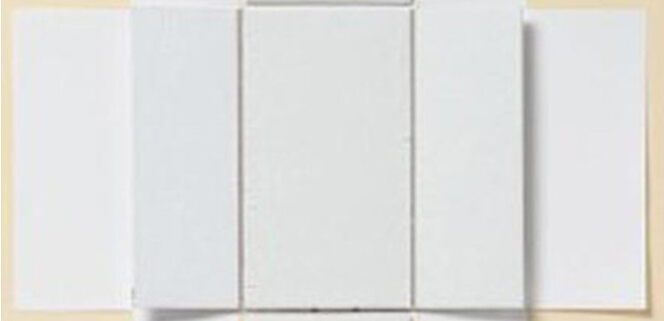

It’s amazing that there’s a decorative paper pasted outside the frame. In order to make the corner clear, the “iPhone” series package boxes used the high cost “V cutting” method for the base-cardboard. But the real innovation that Apple has set off on the packaging is actually a decorative paper wrapped around the core. Known as the “wings” to smear glue wrapped in the box body side part. In this way, there is no drop in the side surface, and the surface is as smooth as a newly cut bean curd.

Decorative paper outside, As known as “wings”. In addition, the medial iPhone box also has obvious characteristics, that is part of the decorative paper is folded inwards to completely cover the inner side of the box body. The usual leather cardboard box is only about 1 to 2 centimeters at the edge of the box. It is reported that the production of iPhone cellphone packaging cartons is made by Italy EMMECI company box machine “MC-2004MEBST-HM”.

For the traditional box machine to break the box in the side wings paste varus part and paste the part. iPhone packaging box so large area of packaging paper, at the same time pasted in the words and so part of the “fight”, the effect of sticker is not beautiful enough. Moreover, the size of the pasted parts can not reach the requirement of sticking the side of the whole box. The EMMECI box making machine is equipped with the structure of left and right paste. Each paste action is controlled by different motors, and the carton produced can meet the quality required by apple.

However, it would be too indiscreet to think that the iPhone package could be made if it had this device. When the paper is slightly inadvertently expanded, it will not only greatly affect the accuracy, but also cause warping and bending. It is also important to choose and paste adhesive for paper that is not flexible and easy to glue. If you do not do the best in every process, you can’t do it at all.

Phone Packaging box is also one of the important commodity competitiveness to cell phone manufacturers. Apple mobile packaging boxes are made in mainland China and Taiwan mainly, it has completely squeezed the cost with the advantage of scale production, that is undoubtedly a very bold investment. Without such a firm belief, it would never be possible to create such a box.

返信を残す

ディスカッションに参加したい?遠慮なく投稿してほしい!